Replacement of bearings

Component replacement principles

Generally, karts must be raced ‘as supplied’ but there are also a few exceptions to this rule. Replacing damaged and/or worn parts on a kart fall into three categories, viz.

Items that must be replaced with parts supplied by the kart’s OEM. Examples are bodywork items such as a spoiler, rear bumper, etc. In other words, you cannot simply use parts from Manufacturer X’s kart on Manufacturer Y’s kart.

Items that must be replaced with OEM parts, but not necessarily those of your kart manufacturer. An example of this is the braking system where you are allowed to use the whole of a braking system (master cylinder, calipers and rotors) from another manufacturer on your kart, providing the replacement system is CIK homologated.

Items that are free choice. Inter-alia, components such as nuts and bolts, the kart’s seat, caster/camber adjusters, and also bearings fall into this category.

Understanding degrees of freedom

A body that is unconstrained in space essentially has 6 degrees of freedom (DOF) as shown in the diagram. It can move along any one of three axes, rotate about these axes, and also change position using a combination of these movements.

Joints that connect bodies in this system remove degrees of freedom and reduce mobility. As an example, a door hinge or a slider on a kitchen drawer each impose 5 constraints and therefore remove five DOF, whilst a tightly bolted joint can remove all of these degrees of freedom. Bearings fall into the category of a joint, and the ones we commonly use in karting can remove 3, 4 or 5 of these movements.

Bearing types used on karts

The majority of bearings used on karts are of the single row deep groove variety that essentially limit the DOF to one motion viz. rotation about an axis. Others, such as the inserts used on the rear axle are also single row deep groove bearings, but they have a spherically shaped outer housing. Referring to the diagram on the RHS, this allows 2 DOF viz. rotation about the major axis and also a certain amount of misalignment or twist around an axis perpendicular to this.

Because of their construction, the rod ends (also known as tie rod ends, Rose joints or Heim joints) fitted to either end of the track rods on the steering system, can allow 3 DOF but usually only 2 as axial movement (along the bore of the inner) is removed because it is trapped by a nut. The outer surface of the inner portion of the joint has a spherical shape that allows it to rotate and also twist inside of a correspondingly shaped non-metallic insert fitted to the outer housing as shown in the sectioned sketch.

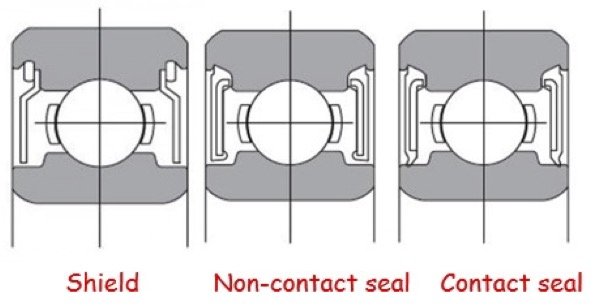

The first type mentioned, viz. single row deep groove ball bearings, are the most widely used bearing type and are available either with shields, seals, or open i.e. used on applications where lubrication is available such as inside the crankcase of an engine. The bearings used on a kart external to the engine are usually supplied pre-lubricated i.e. effectively maintenance free. Being pre-lubricated, the lubricant needs to be contained within the bearing housing via some form of capping arrangement. Because bearing performance and service life are so closely tied to the effectiveness and cleanliness of the lubricant, the seal is a key component. As mentioned earlier, this can be in the form of a metal shield, a non-contact rubber seal, or a contact seal that is held against the rotating shaft either by a spring or the natural shape of the rubber itself – refer diagram below that indicates the differences.

A shield is primarily intended for applications where the inner ring rotates, and can be supplied as a single shield denoted by the suffix –Z (shield only fitted to one side of the bearing) and –ZZ or ‑2Z (shield on either side) after the bearing number. They are made of thin sheet steel and are fitted by the manufacturer into the outer ring thus forming a narrow gap with the inner ring. They are also the least expensive, provide a good containment for the lubricant, and offer zero friction in the process - for these reasons, a shielded bearing is the preferred choice for use on a kart.

Non-contact seals are the next most logical choice, but are more expensive that it’s shielded counterpart and typically have a –RSL or -2RSL suffix attached to the bearing number. Whilst contact seals provide the best protection against contamination, there is an increase in rotational torque due to friction between the seal lip and bearing inner ring and these bearings have a –RST or -2RST suffix and are not normally used on a kart. Sealing performance is a trade-off between protection and torque, so choose carefully.

Rear axle bearing inserts

The bearing inserts used here are equipped with a set of grub screws fitted to the inner ‘race’ of the bearing, and they allow the axle to be locked axially into the correct location w.r.t. the centre of the kart. They are each fitted inside a cassette, which is specific for the chassis size and kart manufacturer, and which are bolted into the uprights that are welded onto the rear of the chassis. When fitting new cassettes and/or re-fitting or changing an axle, it is imperative that as little axial force as possible is applied to the axle itself. Referring to a previous diagram that indicates a small amount of angular misalignment being possible, such misalignment can only be in one direction. Having to hammer the axle into place is a pretty good indication that the bearings are not 100% in line with each other to start with.

Loosening off the cassettes themselves in the uprights before attempting to refit the axle therefore assists in the alignment process and ensures that you have the least amount of binding trapped into the bearings after everything is finally tightened up again. Notice that the bearing insert is not symmetrical i.e. it is longer on one side because of the space occupied by the grub screws. When fitting the bearing inserts ensure that both the longer sides either face towards the centre of the kart, or point outwards, as these ‘extensions’ have an influence on axle stiffness.

The choice of a replacement bearing is dependent on the axle diameter and also the bore of the cassette, which is usually a standard size based on the bearing’s inner diameter, but there is one exception on certain 1050mm non-DD2 chassis. Replacement bearings with typical SKF designations (remember to add the suffix for shields or seals) are shown in the table below. If you unluckily have a 50mm axle that requires an 80mm OD bearing, then those replacements are usually ex-import as not too many local outlets keep them in stock. FSK in China appear to be one manufacturer of this bearing.

Front wheel and/or hub bearings

Essentially there are four different sizes in use as shown in the table below. Hence it’s a good idea to double check the existing bearing dimensions before you go ahead and possibly purchase the incorrect size. Once again, remember to add the correct suffix for shields or seals dependent on your preference and constraints on the wallet.

Stub axle spindle bearings

In this application, it’s simply a case of knowing whether your kart uses 8mm or 10mm kingpin bolts as there are only two choices of bearing size as per the table below.

Tie rod ends

Although the tie rods themselves are available in a variety of lengths from 190mm up to 290mm, the external shape is invariably a hexagon shape. Some manufacturers make round ones with flats ground onto them to allow a spanner to be fitted for proper tightening against the nut after setting the desired length. Each of the rods are drilled and tapped with a LH thread at one end, and a RH one at the opposite end. The end tapped with a LH thread is usually designated by a shallow groove that is cut into the outer surface of the rod as shown in the RHS picture below.

Luckily, there is only one thread size used on all karts viz. M8x1.25 and the table below provides the Bearing Man Group (BMG) designation for these Rose joints. Other outlets such as a SKF or other bearing distributor are also able to supply equivalents.

Emile McGregor - MSA Technical Consultant